“I don't stop just because I'm retired”

Innovator: Tage Norén

Innovation: Listjiggen Crown Moulding Tool

When Tage Norén was installing ceiling mouldings in his home, he, like so many others, found it difficult to measure and align them correctly. He therefore decided to develop a tool that makes it easier to install ceiling mouldings. No sooner said than done - with the moulding tool Listjiggen, he has made it easier for DIYers to saw ceiling mouldings.

The moulding tool Listjiggen was developed by Tage Norén from Mullsjö in Västerbotten, who has worked for RISE SMP Svensk Maskinprovning AB for many years. In addition to being involved in evaluating products, Tage has also manufactured testing equipment to enable the products to be properly evaluated.

Tage's creativity, together with the knowledge he has acquired over the years by drawing on the computer, made it possible to quickly produce a 3D prototype of the moulding jig. And with the help of the Vännäs workshop, he was able to print the prototype. After some fine-tuning, the moulding jig was completed and the moulding tool was manufactured by Ågrens mekaniska in Strömsund in 2020.

What makes your innovation unique?

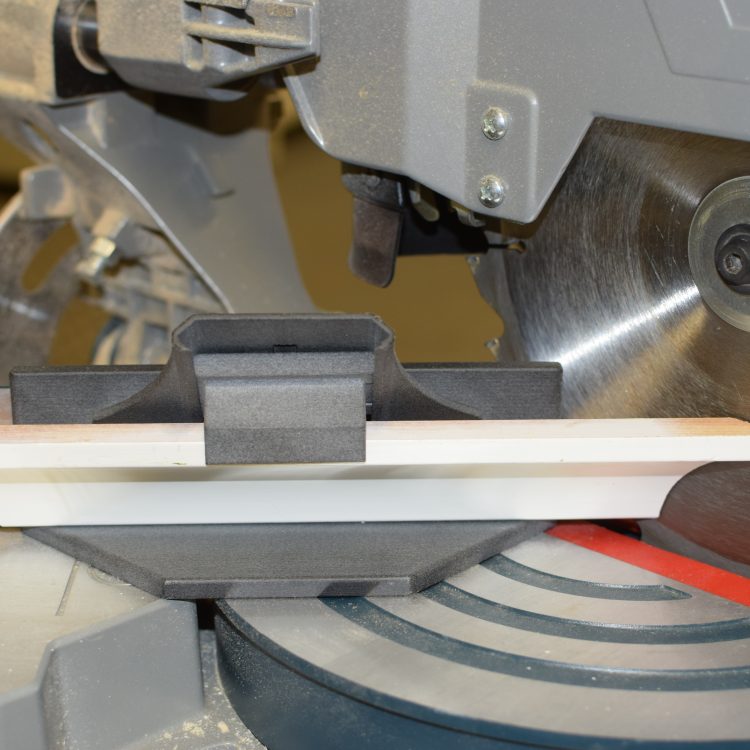

- The moulding jig is the solution for easily fitting your ceiling mouldings. You avoid all the twisting and turning with the moulding, and simply cut the moulding in the same position as it will sit on the ceiling.

Who can benefit from your smart moulding jig?

- There are both amateurs who buy it and also carpenters who do not cut mouldings very often. I'm very happy to be able to help them with this step!

How has the response from the neighbourhood been?

- It has been great fun to get out on the market and show off the product! Both through retailers like you at SmartaSaker, but also to see happy shouts in social media. With an e-retailer, I am now in place one of the 100 most popular products - which feels great!

- In total, I have sold about 4-5000 list jigs and not a single customer has come back and said that this was not what they wanted. Not a single customer has come back - I live on that.What challenges have you faced during the process?

- I already have some experience and have developed several other products, so the process has gone smoothly. But you have to expect that it takes a lot of time from idea, to prototype and finished tool. An important part of the process has been to have someone to discuss the idea with. A person you can trust. It's never wrong to take impressions from others! You may feel that this is ‘hallelujah!’ but that's not always the case,’ Tage laughs.

What has been easier during the work?

- Thanks to today's technology, it goes very smoothly. I send a 3D drawing to a company that has equipment to produce a prototype through a 3D printer. It's an amazing technology! The cost per prototype is around SEK 6-700 and it took three attempts before I was completely finished with the list jig. If you had developed the tool directly, however, it would have cost around SEK 100,000, roughly speaking, which is expensive if you need to change something.

And what part of the innovation journey are you most passionate about?

- ‘It's the work of developing the actual solution. That's what I've been working on all these years and it's always been fun. Even while working on the list jig! I've always had good and rewarding jobs, but I'm not stopping just because I'm retired...

Three tips for other innovators:

Check your idea with a person you trust.

Be patient and don't be in a hurry - let the process take time.

Get out there and showcase your idea in different markets. Start a Facebook account to showcase and promote your products!

When Tage Norén was installing ceiling mouldings in his home, he, like so many others, found it difficult to measure and align them correctly. He therefore decided to develop a tool that makes it easier to install ceiling mouldings. No sooner said than done - with the moulding tool Listjiggen, he has made it easier for DIYers to saw ceiling mouldings.

The moulding tool Listjiggen was developed by Tage Norén from Mullsjö in Västerbotten, who has worked for RISE SMP Svensk Maskinprovning AB for many years. In addition to being involved in evaluating products, Tage has also manufactured testing equipment to enable the products to be properly evaluated.

Tage's creativity, together with the knowledge he has acquired over the years by drawing on the computer, made it possible to quickly produce a 3D prototype of the moulding jig. And with the help of the Vännäs workshop, he was able to print the prototype. After some fine-tuning, the moulding jig was completed and the moulding tool was manufactured by Ågrens mekaniska in Strömsund in 2020.

What makes your innovation unique?

- The moulding jig is the solution for easily fitting your ceiling mouldings. You avoid all the twisting and turning with the moulding, and simply cut the moulding in the same position as it will sit on the ceiling.

Who can benefit from your smart moulding jig?

- There are both amateurs who buy it and also carpenters who do not cut mouldings very often. I'm very happy to be able to help them with this step!

How has the response from the neighbourhood been?

- It has been great fun to get out on the market and show off the product! Both through retailers like you at SmartaSaker, but also to see happy shouts in social media. With an e-retailer, I am now in place one of the 100 most popular products - which feels great!

- In total, I have sold about 4-5000 list jigs and not a single customer has come back and said that this was not what they wanted. Not a single customer has come back - I live on that.What challenges have you faced during the process?

- I already have some experience and have developed several other products, so the process has gone smoothly. But you have to expect that it takes a lot of time from idea, to prototype and finished tool. An important part of the process has been to have someone to discuss the idea with. A person you can trust. It's never wrong to take impressions from others! You may feel that this is ‘hallelujah!’ but that's not always the case,’ Tage laughs.

What has been easier during the work?

- Thanks to today's technology, it goes very smoothly. I send a 3D drawing to a company that has equipment to produce a prototype through a 3D printer. It's an amazing technology! The cost per prototype is around SEK 6-700 and it took three attempts before I was completely finished with the list jig. If you had developed the tool directly, however, it would have cost around SEK 100,000, roughly speaking, which is expensive if you need to change something.

And what part of the innovation journey are you most passionate about?

- ‘It's the work of developing the actual solution. That's what I've been working on all these years and it's always been fun. Even while working on the list jig! I've always had good and rewarding jobs, but I'm not stopping just because I'm retired...

Three tips for other innovators:

Check your idea with a person you trust.

Be patient and don't be in a hurry - let the process take time.

Get out there and showcase your idea in different markets. Start a Facebook account to showcase and promote your products!

_098_750.png)

_750.png)

_750.png)